NEW PRODUCTS LAUNCHED

We love to innovate and constantly improve our window cleaning tools. Check out the latest tools!

E-FORCE

E-FORCE, for Low-E Glass

The last bastion of Window Cleaning (well the latest challenge) is to clean Low-E Glass EFFICIENTLY within the guidelines of the Manufacturer’s specifications.

Low E coated glass has a very thin metal coating on the interior glass surface. This tin coating gives the window its improved thermal insulation and solar control performance compared to ordinary clear glass. The coated surface side of Low-E Glass is to be cleaned differently to ordinary glass.

Firstly, we should say this will not affect every window cleaner. If you service well established homes, you are unlikely to come across Low-E glass (heat efficient). If you service an area that gets very cold, or very hot, you are likely to service 'double glazed' windows, in which case, if Low-E Glass is installed, the Tin-Side will be on the Inside!

The application for E-FORCE is in towns and cities with new home builds with single glazed instals - i.e. the outside is normal glass, and the inside is Low-E coated. The Low-E coating is EXTREMELY soft and easily marked - so much so that the manufacturers recommend ONLY soft cloth cleaning (see links at bottom of page).

As more and more homes are built with Low-E glass, our problem has multiplied … and the only close solution is Unger’s STINGRAY which does not offer efficiency, or affordability.

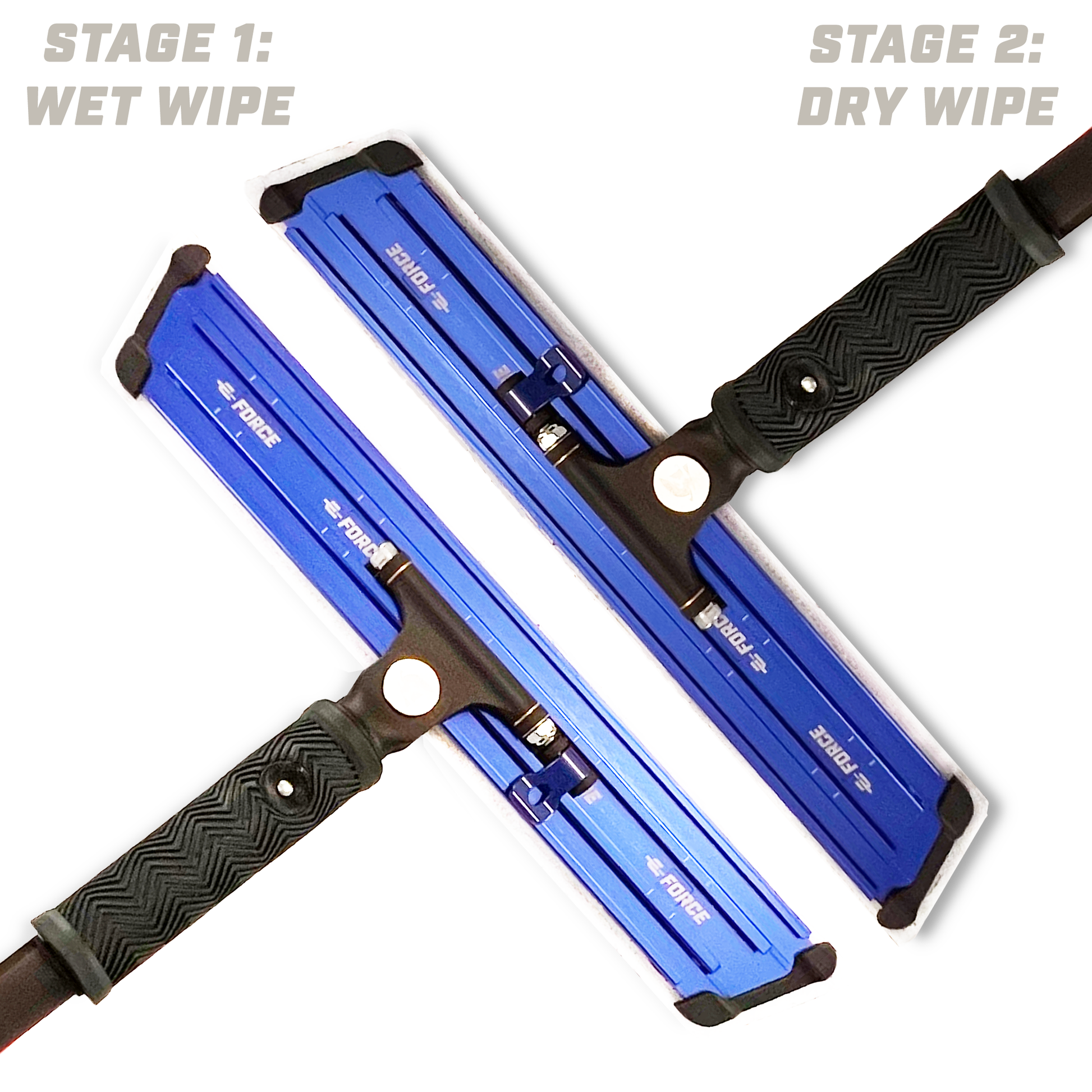

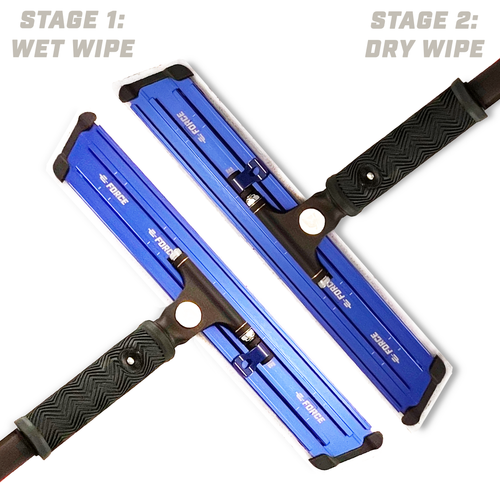

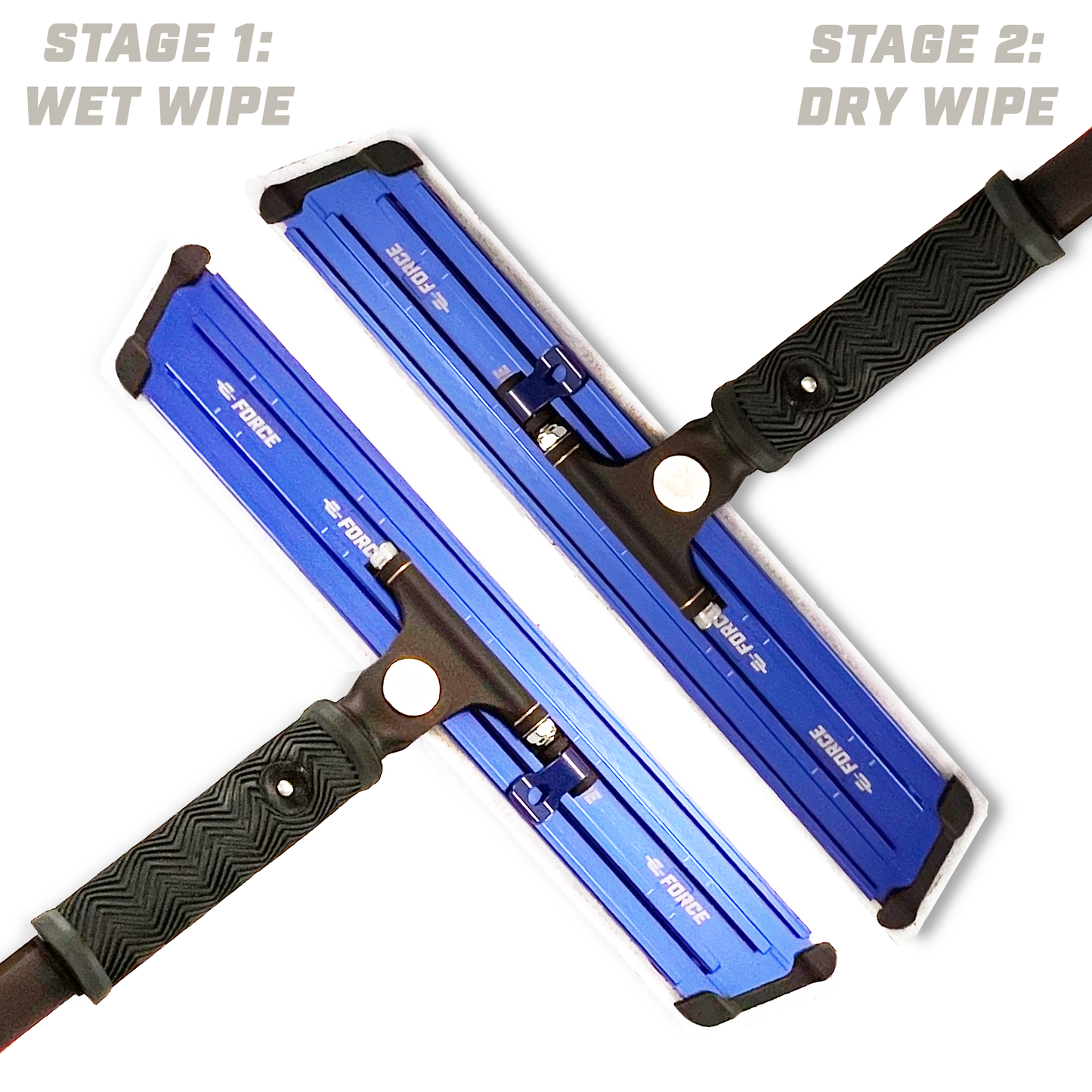

E-FORCE is our new Low-E Glass Tool Set. E-FORCE also comes with a technique. Cleaning E-Glass is not fast - and use the wrong tools on the glass, and you void the warranty, potentially triggering an insurance claim against you that your insurance company may not be happy to cover.

Accordingly, you can only use : SOFT CLOTHS and MICROFIBER.

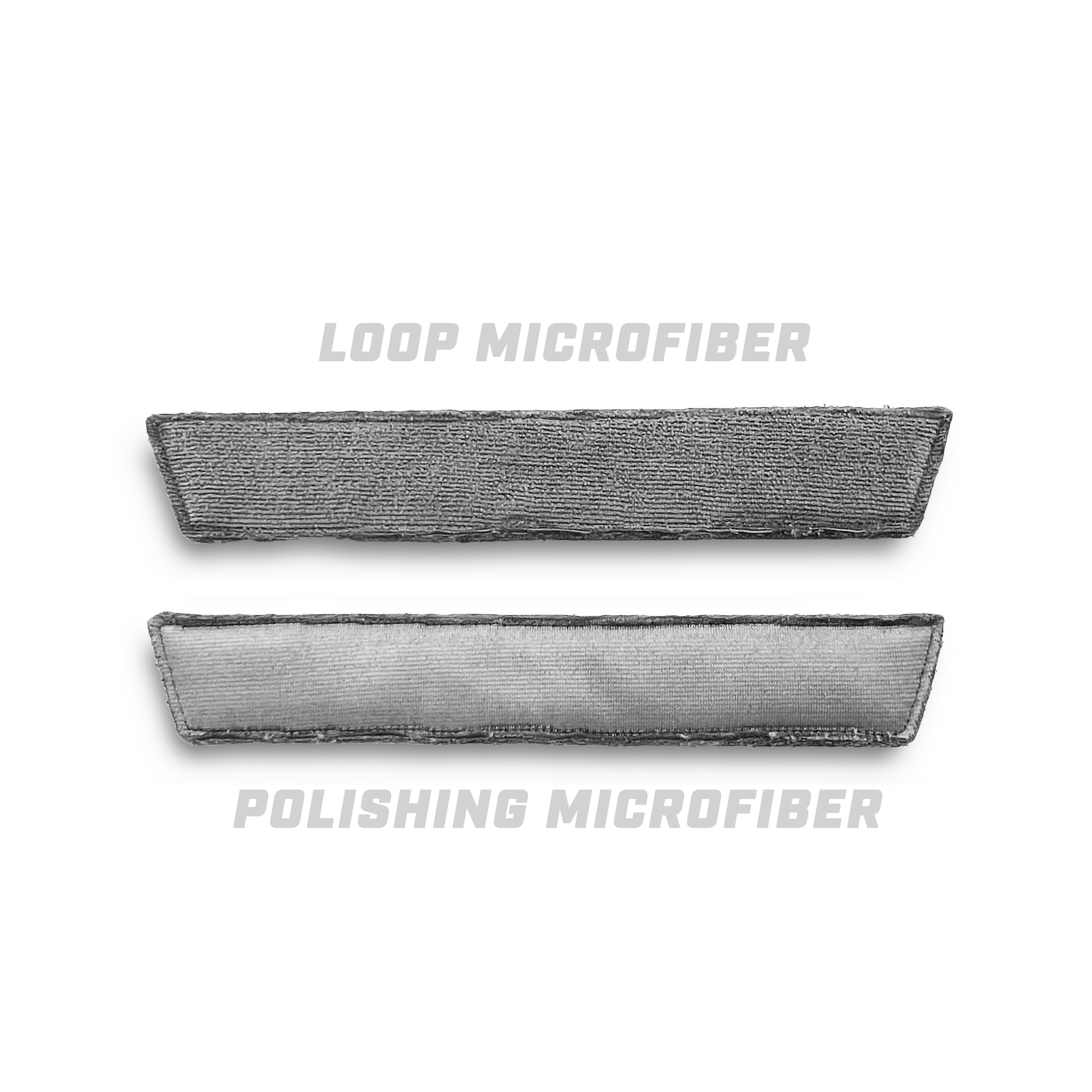

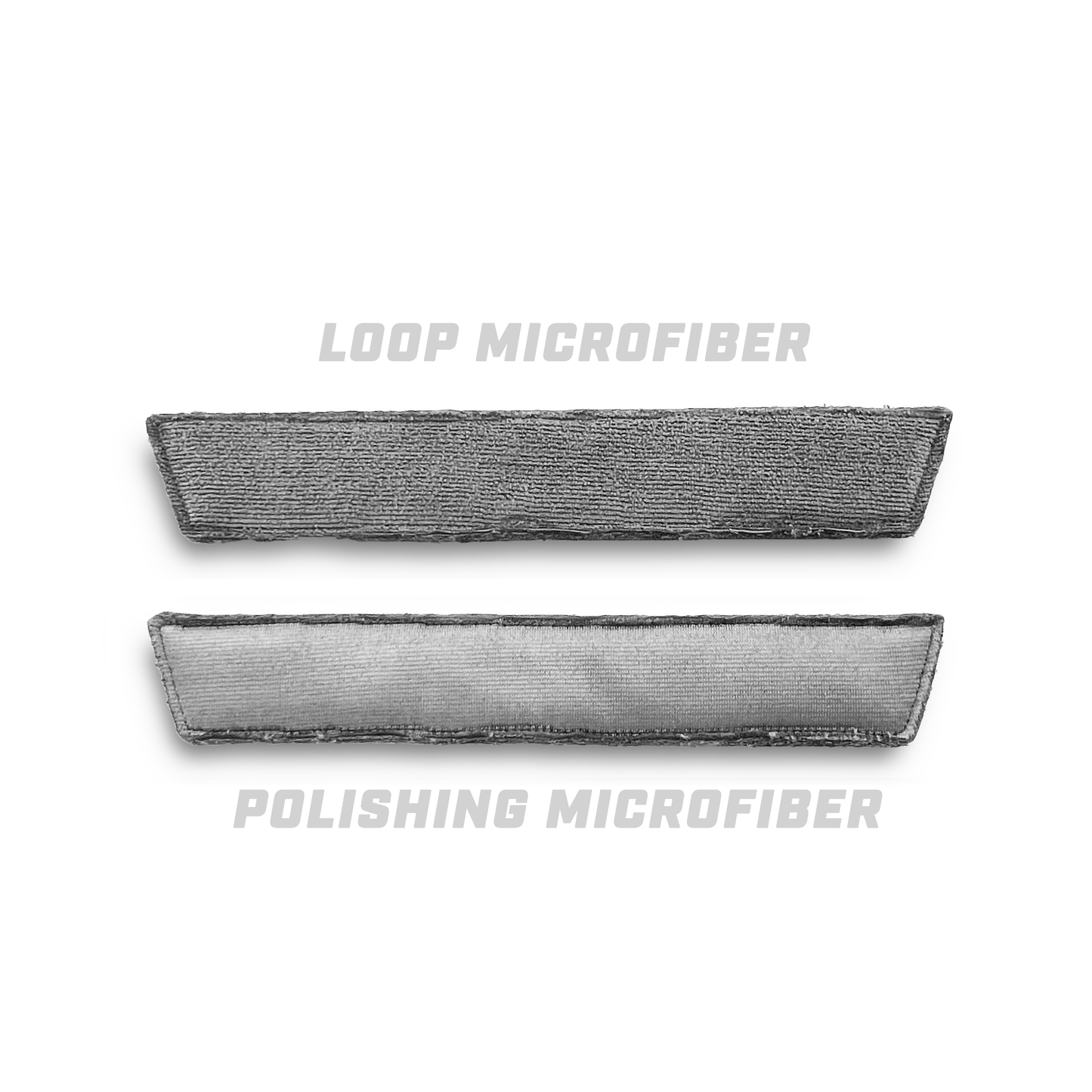

MICROFIBER (used correctly) 'grabs' dirt and holds it - that is what makes microfiber special - it can even grab and hold bacteria! So the first E-FORCE SCRUB (Step 1) is to use a long-loop (increased surface area) microfiber to grab the dirt off the window.

We need to use a fine mist of water (or water and iso mix) as your 'surfactant ' to get the 'grab' microfiber to slide across the Low-E surface. Inevitably , this pad leaves a super fine film of water after each pass which, when the water evaporates, leaves a very fine film of dirt on the window that can often only be seen at sunrise and sunset.

This is why Step 2 is critical - it is a 'polishing' of the window with a dedicated glass polishing microfiber, and no water. This is why the microfiber of choice for Step 2 is a 'shiny' microfiber.

Included in your Pack :

2 x E-FORCE plates

2 x SLIDERs

2 x STRAIGHT STEM (REACH-iT and GARDINER compatible) OR 2 x 40 TEETH Pole Stems.

1 x 60 degree POLE STEM (REACH-iT)

3 x LONG LOOP MICROFIBER (Step 1)

3 x MED LOOP MICROFIBER (Step 1)

3 x POLISHING MICROFIBER (Step 2)

OPTIONS:

2 x G-FORCE PRO POLES (8FT extended)

1 x G-FORCE PRO POLE

* E-FORCE is inspired by Byron Guest (MODMAN), from Perth, Australia.

E-FORCE is available now to customers, however, not available through Distributors till full mass production in April 2024

Glass Manufacturer Websites with Low-E Glass cleaning guidelines :

https://www.viridianglass.com/

www.customglassproducts.com.au

The BEST reference information on how to clean Low-E Glass

Hand Cleaning Low 'E' Glass

Low 'E' Glass has a thin coating to the inner face of the glass. It is this hard and durable coating which gives the glass its thermal insulation and solar control performance compared to ordinary clear glass. The coated surface of Low 'E' glass does not need to be cleaned differently to ordinary glass and the following guidelines are recommended for the best hand cleaning results.

Routine Cleaning

Hand cleaning of the coated (interior) surface of the Low 'E' glass to visibly remove accumulated dust or fingerprints, can be accomplished using a number of different glass cleaning products. The exterior surface of the glass is not coated and can be cleaned in the same fashion as ordinary glass.

Recommended Routine Glass Cleaning

A mixture of one part vinegar with ten parts water Vinegar based glass cleaners have generally demonstrated an ability to provide a clean and streak free glass surface. Do not use ammonia based or alcohol based glass cleaners because these cleaners tend to leave visible streaks.

Routine Cleaning Procedure

Flood the glass surface with the spray on cleaning solution or with a cloth saturated in cleaning solution. Be generous with the amount of solution applied.

Scrub the wet area with a clean, lint-free towel or cloth.

Wipe dry with a dry, clean lint free towel or cloth. DO NOT USE A SQUEEGEE on the Low'E' coated (interior) surface.

To prevent streaking, stop wiping when the glass is almost dry and there is a uniform film of moisture left on the glass surface.

Under no circumstances should razor blades or squeegees be used on the low E coated (interior) face of the glass

Spot Cleaning

Occasionally, spot cleaning may be required to remove stubborn dirt or foreign material that may adhere to the Low 'E' coated surface. Spot cleaning products work to remove markings from grease, oil, tape adhesive and crayons or other waxy material as well as paint and rub-off marks from plastics.

Recommended Spot Cleaning Products

Acetone (solvent available from hardware stores)

Spot Cleaning Procedures

Carefully follow the chemical manufacturers instructions

Apply a small quantity of the cleaner listed above to clean, wet cloth or towel Rub onareas of glass needing spot cleaning

Wipe clean using a dry, lint free towel or cloth followed by a routine cleaning procedure

Specialised Cleaning

Do not use razor blades, steel wool or other metallic objects on the Low 'E' coated surface. If metallic objects contact the coated surface, a thin layer of metal removed from the object may be deposited on the Low 'E' surface which results in a discolored stain which is difficult or impossible to remove using normal cleaning procedures.

Recommended Specalised Cleaning Products

Hydrochloric Acid (available from hardware stores) diluted to 99% water to 1% hydrochloric acid

Specialised Cleaning Procedure

Carefully follow the chemical manufacturers' instructions

Apply a small quantity of the specialized cleaner listed above to a clean, wet cloth or towel. A cotton bud may be used for thin line type marks.

Rub on areas of glass needing cleaning

Wipe clean using a dry, lint-free towel or cloth followed by a routine cleaning procedure.

Ensure that the cleaner does not come into contact with framing materials

The above information is offered for assistance in the application of flat glass products, BUT IT DOES NOT CONSTITUTE A WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. Actual performance may vary in particular application.

Source: www.customglassproducts.com.au

E-FORCE is inspired by Byron Guest the 'MODMAN' from Perth, Australia.