ANOTHER REACH-iT INNOVATION - circa 2023

Whilst there is a feeling that motorized solar panel cleaning pole tools are efficient, a study of YOUTUBE videos can quickly disprove this. In addition, the motorized brushes use heavy bristles that potentially damage the SOLAR PANEL glass. We have attempted to make 3 different versions of motorized roller and rotary brushes that overcome these drawbacks, but we always came to the same conclusion : they are not fast enough - nowhere near the league of SOLAR ROCKER.

The target is to effect a clean solar panel in less than 10 seconds per panel. This means you want to choose the best SCRUB PAD to match what you are removing from the panel and you ideally want to clean the panel with two strokes following the left frame, two strokes following the right frame, and overlap in the middle (nothing more to do). This is the basic advantage of SOLAR ROCKER over motorized panel cleaners, without the complications of extra heavy tools, and the need for electrical power.

SOLAR ROCKER is designed to clean solar panels fast. Panels that are treated with ARC (Anti-Reflective Coating) need non-abrasive contact, lest you damage the coating and create hot/cold spots on the wafers that put a panel out of 'balance' thereby initiating a panel failure, that leads to an array failure. SOLAR ROCKER has a SILICON BRISTLE SCRUB for ARC treated panels. SILICON has a high friction (drag)co-efficient, so it is very effective at 'grabbing' dirt and debris off the panels.

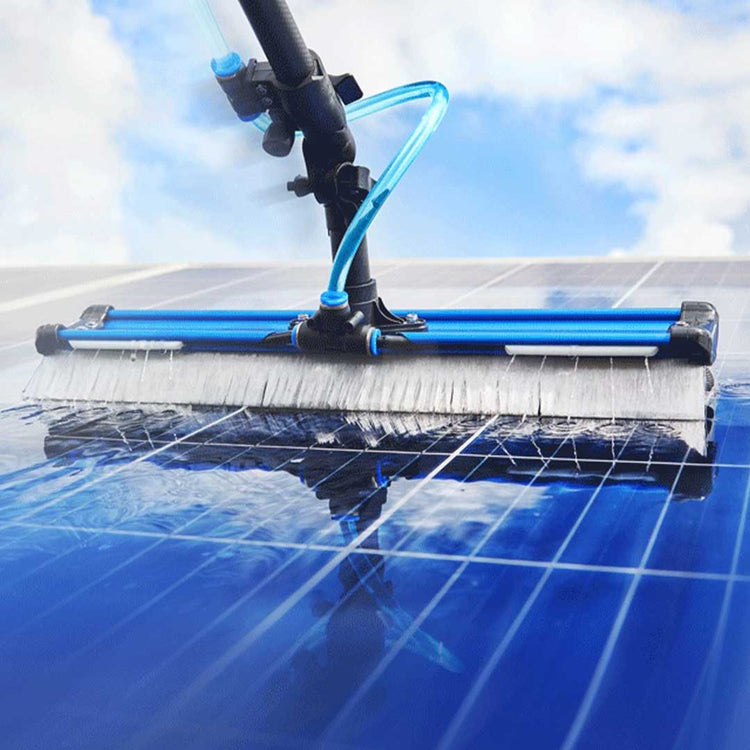

When we clean windows, if you think about it, we push 'sh!t' up hill and ask gravity to pull the dirty water off the vertical window. Solar panels are pitched at anywhere between 0º and 60º depending on the distance from the equator. The lower the pitch, the less effective is a gravity rinse. The dirt quickly drops out of the rinse water and stays on the panel. This is why SOLAR ROCKER is designed with only 8 rinse jets on the 'high side' and 26 jets on the 'low side'. The high jets wet the panel so the water is acting as a surfactant to assist the glide of the brush. The low jets are doing the real rinse work. By pulling (or pushing) the brush downwards on the panel, the majority of the water is cascading FASTER than a gravity rinse, thereby turbulating the water and keeping the dirt in suspension till it is pulled completely off the bottom of the panel. This feature massively reduces the number of cleaning strokes needed to clean the panel.

Whether you are cleaning from above the panel (like from the apex of the roof) or from below the panel (like from the ground), SOLAR ROCKER can be adjusted to ensure the 26 jets are always on the 'low side'.

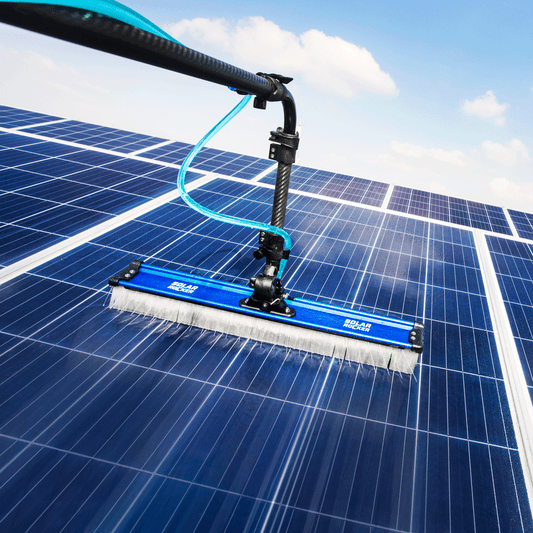

As the operator cleans each solar panel, the angle of the pole in relation to the panel surface changes - that is why we have the 'ROCKER' function - a 20º range in motion ensures the SCRUB of choice (we have 6 different SCRUBS) will always remain flat on the panel surface, maximizing the AGITATION, reducing the number of strokes needed to effect a clean surface.

Some operators like the swivel function of the PIVOT as it can make it easier to move the brush horizontally across the solar array, however, there is more stability in locking the PIVIT with PIVOT LOCK, so SOLAR ROCKER comes with PIVOT LOCK fitted. It is easily removed and re-attached to suit your preferences.

SOLAR ROCKER is available in 16" and 22" for standard 39" wide panels and 26" for the larger panels found on SOLAR FARMS.

For debris that is not water soluble, consider Z-FORCE with plastic blades. This will remove lichen and paint overspray quickly.

SAVE 10%

SAVE 10%